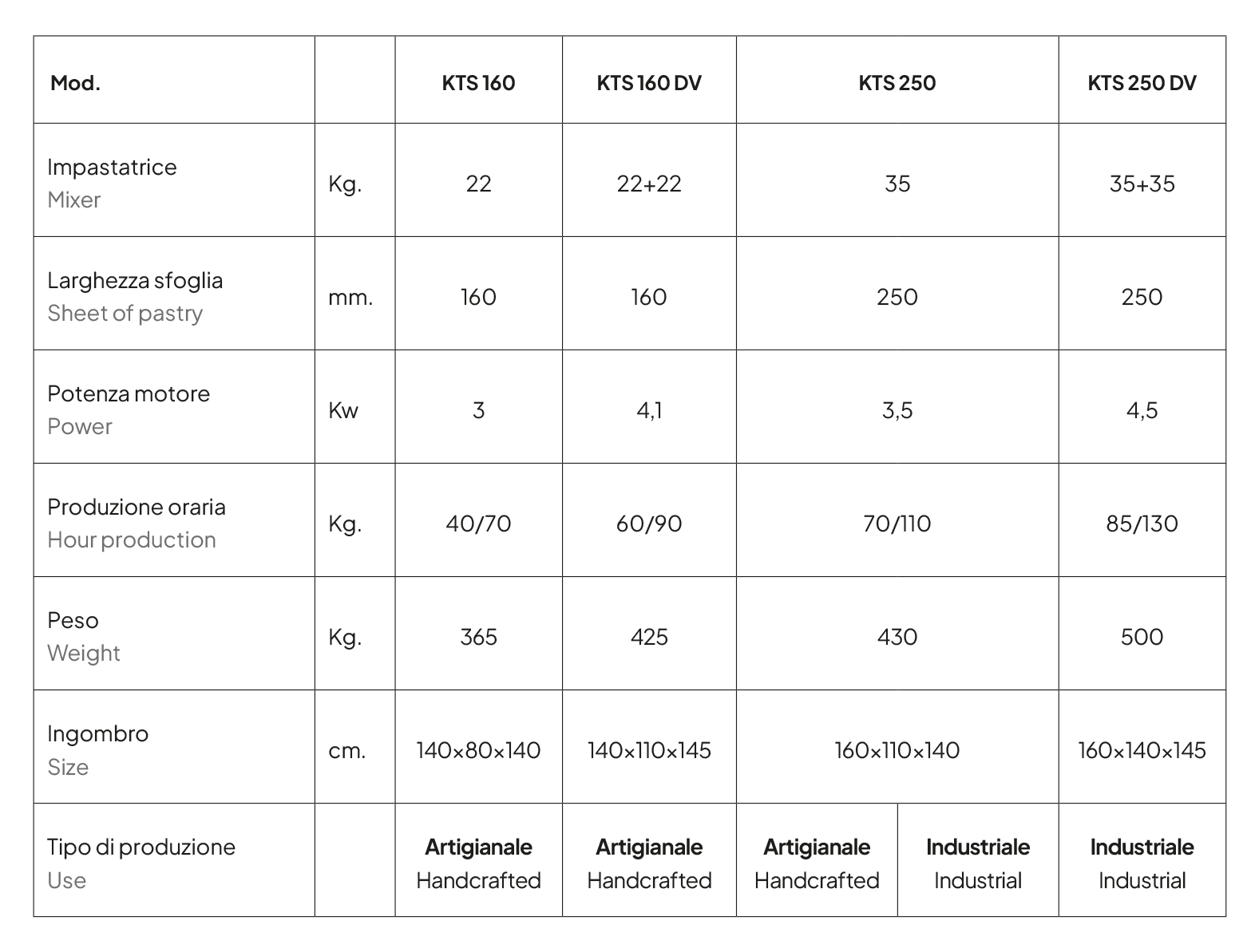

KTS 250 DV

Production:

Handcrafted

The machine produces the following formats:

| Sheet |

Automatic Double-tanked Combined Group for the Production of Puff Pastry and Long-cut Pasta, Ramen

The automatic combined group is perfect for the production of puff pastry, long-cut pasta, tagliatelle, tagliolini, angel hair, pappardelle, fettuccine, noodles, spaghetti alla chitarra, lasagna and ramen.

Main components

Automatic sheeter

Equipped with two tanks with a dough capacity of up to 35 kilos, extractable shaft-blades and independent motorization.

Laminator

The automatic laminator group has a width of 25 cm and stainless steel rollers with a special profile, capable of rolling 2.5 kilos of pastry per minute. The calibrators are designed to roll the dough without stress, avoiding heating and guaranteeing a pastry with ideal organoleptic qualities.

Maintenance and Cleaning

All mechanical parts and bearings are maintenance and lubrication-free, spaced to facilitate cleaning and prevent contamination.

Independent Motorization

The independent motorization allows you to roll the rolling pins of the dough even during the production of pasta and tagliatelle, without interrupting the production cycle. The motorized belt allows you to automatically roll the dough and set the size of the single roll.

Automatic pasta cutter

Equipped with calibrating rollers 25 cm wide and increased to ø 55 mm, mounted on lubrication-free bearings. It automatically produces dough for lasagne, tagliatelle, fettuccine, tagliolini, angel hair, pappardelle and spaghetti alla chitarra, with the desired thickness and length.

Precision

This equipment allows you to precisely predetermine the thickness, length and width of the cut, with interchangeable dies in a few seconds.

Optional

Flour sprinkler: to process pastry to powder.

Ramen version: For the specific production of ramen, the dough cutter is equipped with special supports to optimize the production cycle.